PRODUCTS

Need a reliable custom cable maker? Winfox is here to provide specialized cables that meet specific requirements for new products and enhanced applications.

Custom Cables for Specialized Applications

Are off-the-shelf cables failing to meet your unique requirements? Whether you need cables for advanced medical equipment, industrial automation, robotic arms, or high-performance audiovisual systems, Winfox delivers custom cable solutions built to your exact specifications.

With over 30 years of experience and ISO 9001:2015 certification, we specialize in creating high-quality cables for diverse industries and applications. Our extensive range of materials and options includes copper, gold-plated, and specialty conductors, durable insulation materials like PVC, silicone, and LSZH, as well as advanced shielding designs to ensure durability and reliability.

We offer flexibility at every step—no minimum order requirements, fast turnaround times as quick as 3 days depending on complexity, and expert solutions tailored to your needs. From concept to delivery, Winfox ensures your cables perform under any conditions. Don’t settle for standard solutions when we can create the perfect cable for you.

Contact us today to get started!

What is Custom Cable Assembly?

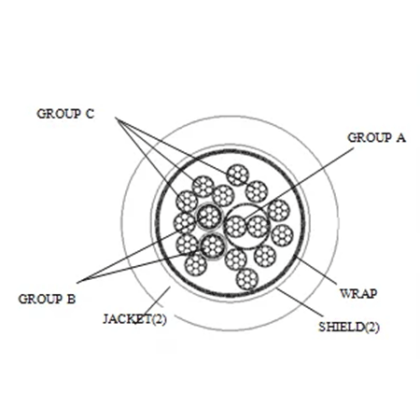

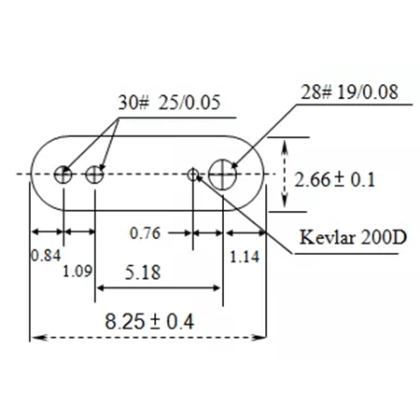

Custom cable assembly is the process of manufacturing and designing cables tailored to meet specific needs or applications. Unlike standard cables, these are built to fit special requirements, whether it's for size, shape, materials, functionality, or performance. They combine different components like conductors, insulation, shielding, wire gauges, jackets, and connectors to create a cable perfectly suited to its purpose and settings.

The key features of custom cable assemblies include flexibility in design, improved durability, and optimized application performance, whether for medical, industrial, or even aerospace uses. They offer solutions where off-the-shelf cables cannot deliver, making them indispensable in industries with complex or unique demands.

Why Choose Winfox for Custom-made Cable Manufacturing: Capabilities and Advantages

|

|

|

|

|

|

|

|

|

|

|

|

|

|

How to Order Custom Cables from Winfox

Step 1: Share Your Requirements

Tell us your specifications, lengths, materials, and purpose. We accept sketches, blueprints, or CAD files to ensure accuracy and streamline the process from the start.

Step 2: Design Review & Optimization

Our experts evaluate your needs and suggest the best design to ensure performance, durability, and cost-effectiveness.

Step 3: Get a Fast Quotation

Receive a clear, detailed quote that covers pricing, timelines, and all the essentials to move forward confidently.

Step 4: Sample Creation

We craft a sample cable tailored to your specs for you to test and approve.

Step 5: Confirm & Finalize

Once you’re happy with the sample, give us the green light to proceed. Adjustments? No problem!

Step 6: Production with Precision

We kick off mass production using top-notch materials and rigorous quality control to guarantee excellence.

Step 7: Fast & Reliable Shipping

Your cables are packed securely and shipped to you within 3 days to 2 weeks, depending on order size and location.

Ready to get started?

Contact Winfox today and bring your custom cables to life—effortless, fast, and tailored just for you!

What We Offer for Custom Cables: Our Options

At Winfox, we specialize in designing custom industrial cables, medical cables, audio cables, and more, tailored to meet specific industry needs. Our extensive customization options cover a wide range of materials, shielding, fillers, and cable types, ensuring that every solution aligns with performance, safety, and aesthetic requirements.

Conductor Materials

We offer a wide range of conductor materials to suit various electrical and mechanical needs.

Our selection includes copper and copper alloys, such as bare copper, tin-plated, nickel-plated, and silver-plated copper. These materials provide excellent conductivity and resist corrosion effectively. For demanding environments, we also offer specialty options like cadmium copper or copper-clad steel, which provide additional strength and durability.

Nickel and nickel alloys are also available, performing well in high-temperature or corrosive environments. These materials are ideal for industries like aerospace and other demanding applications.

For specialized uses, we offer noble metals and precious coatings, including silver and gold. These options ensure exceptional conductivity and durability, making them suitable for high-frequency data transmission and other advanced applications.

Insulation/Jacket Materials

The insulation and jacket of our cables adopt advanced materials to provide optimal protection. Our options include:

- PVC, PE, and XLPE: Cost-effective, durable, and resistant to chemicals, suitable for general and industrial use.

- Fluoropolymers (PFA, FEP, ETFE, PVDF): Excellent for high-performance environments like aerospace and medical applications.

- TPE, TPU (PUR): Highly flexible and durable, perfect for robotic arms and automated equipment.

- Silicone: Heat-resistant and soft, ideal for medical cables and high-temperature environments.

- LSZH (Low Smoke Zero Halogen): Safe for indoor applications where low toxicity is required.

Shielding Options

For environments with electromagnetic interference (EMI), we offer a range of shielding solutions tailored to specific needs. These include spiral and braided shielding, with sizes as small as 50 AWG for compact applications.

Braid shielding, made from woven strands of copper or aluminum, offers strong structural integrity and reduces crosstalk, making it ideal for cables requiring frequent movement. Spiral shielding, often used in audio cables, involves a spiral wire pattern that delivers excellent flexibility for applications with frequent flexing.

We also provide lightweight aluminum mylar and mylar wraps, perfect for data and audiovisual cables, along with specialized materials like e-PTFE and cotton paper for medical and high-flex applications.

Reinforcement Materials Options

Choosing the right cable reinforcement material for fillers and wraps is crucial for ensuring durability, flexibility, and performance. We offer a comprehensive range of high-quality materials designed to meet your specific demands. Here are our options:

- Kevlar: Exceptional strength for demanding environments.

- Nylon Yarn: Flexible and abrasion-resistant, ideal for general use.

- Cotton Yarn: Eco-friendly and suitable for low-stress applications.

- Nomex: Flame-resistant and perfect for high-temperature settings.

- Technora: High tensile strength and durability for industrial use.

- Glass Fiber: Provides strength and electrical insulation.

- Non-Woven Fabric: Lightweight reinforcement with abrasion resistance.

Our experts are ready to help you find the ideal material for your unique needs. Contact us to explore additional options and customized solutions for cable reinforcement.

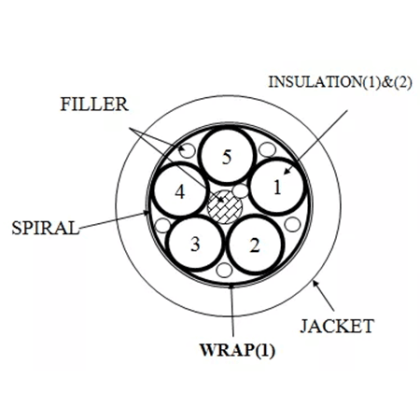

Single Core Wire/Multi-Core Composite

Single core wire consists of a single conductor, typically copper or aluminum, insulated for electrical applications. It's simple and cost-effective, commonly used for general electrical wiring, motor coils, and heating elements. Types vary based on heat or voltage resistance, such as high-temperature or high-voltage-resistant wires.

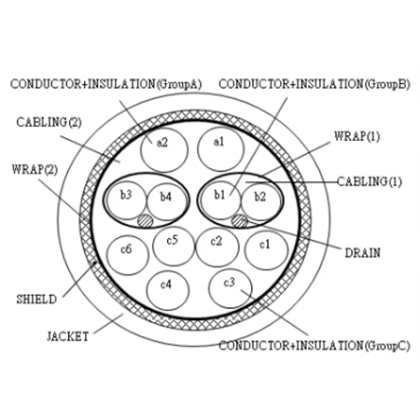

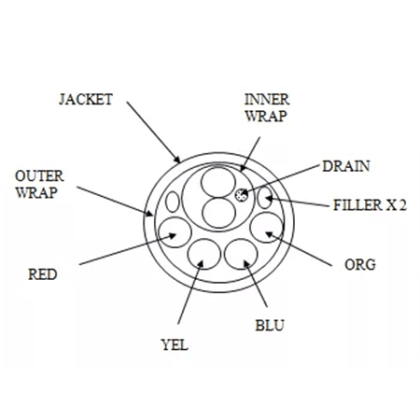

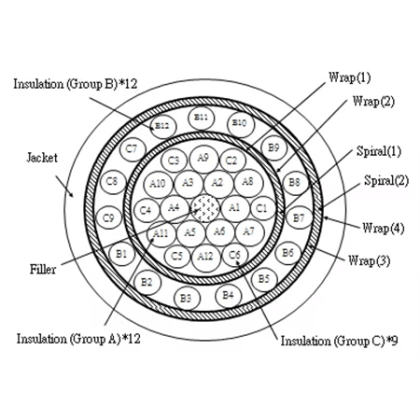

Multi-core cables consist of multiple conductors housed within a single sheath, allowing for the simultaneous transmission of various signals. Our offerings include a wide range of specialized cables, such as medical cables, instrument cables, and anti-theft cables, each tailored to meet specific environmental and functional requirements.

We also provide audiovisual cables, data transmission cables, patented internet cables, and patented telephone wires. Additional options include patented USB cables, robotic arm cables, thermal compensation lead wires, all types of UL cables, coils, and super-soft cables, ensuring a versatile solution for a wide array of applications.

All of the options above offer RoHS-compliant solutions for environmentally safe applications.

Applications

- Medical Equipment: Sterilizable cables designed for diagnostic and surgical tools, ensuring safe and reliable performance in critical environments.

- Automated Systems: High-flex cables built for robotic arms, and automation control, offering superior flexibility and longevity in dynamic, high-motion applications.

- Data and Audio-Visual Equipment: Shielded cables that deliver interference-free signal transmission, ensuring high-quality performance for data and audiovisual systems.

- Exercise Equipment: Durable spring and fitness cables designed for long-term use, withstanding the demands of constant motion and stress.

- Thermocouples: High-temperature-resistant cables crafted for industrial monitoring, ensuring accurate and reliable temperature readings in extreme environments.

Check our manufacturing capabilities for more information on creating customized solutions tailored to your exact needs.

Benefits of Custom Cable: Why You Need It

Standard cables aren’t always up to the task for specialized or demanding applications. Fixed lengths, limited configurations, and poor durability can lead to inefficiencies, compatibility issues, and even system failures. They often can’t handle harsh conditions or meet specific industry standards, making them a less reliable choice for high-performance or tailored requirements. Custom cables, however, overcome these challenges. Here’s why they are the better choice:

Perfect Fit for Your Needs

Custom cables are designed to meet specific requirements, ensuring compatibility with unique applications that standard cables cannot accommodate. Unlike standard cables, which often force compromises, custom cables ensure proper system integration. This reduces errors and improves functionality.

For instance, in aerospace, custom cables might feature lightweight materials and advanced shielding to handle high altitudes and electromagnetic interference. In healthcare, cables used in surgical devices require biocompatible insulation and the ability to withstand frequent sterilization.

Built to Last Longer and Safer

Custom cables are designed for durability and safety. They feature superior construction and materials tailored to their operating environments, such as heat-resistant insulation, waterproof jackets, and abrasion-resistant coatings. These enhancements ensure they have a longer lifespan even in harsh conditions, including extreme temperatures and chemical exposure.

Also, they can incorporate advanced safety features like flame retardancy, low smoke emission, and chemical resistance, making them ideal for high-risk environments while minimizing hazards such as electrical failures or fires.

Versatile Performance

Custom cables are designed to optimize performance and simplify installation. They can combine multiple functions into a single cable. This reduces clutter, makes maintenance easier, and improves system efficiency. For example, in robotics, a custom cable might integrate power, data, and control signals into one flexible assembly, enabling smooth operation in tight spaces with constant movement and bending.

Saves You Money Over Time

Custom cables may cost more upfront, but they save money in the long run. Their durability means fewer replacements and lower maintenance costs. Custom cables also reduce downtime, which can be expensive in industries like aviation or healthcare. Furthermore, efficient installation and better energy use contribute to long-term savings, making them an absolutely smart investment for you.

Aesthetic and Branding Benefits

Custom cables can enhance your brand identity and product presentation as they ensure you stand out with unique cable design, branded labeling, and colors. Aesthetically pleasing and well-organized cables improve user perception while maintaining functionality, making them ideal for consumer electronics and professional installations.

Ready for the Future

Custom cables are adaptable and scalable. As systems evolve or expand, these cables can be modified to meet new needs. They are compatible with the latest technologies and can handle future upgrades. This makes them a forward-thinking choice, especially in industries where innovation and growth are constant.

Winfox: Custom Cable Manufacturer for Your Unique Product Needs

When standard cables don’t meet your product’s requirements, Winfox delivers fully customizable solutions. As a leading manufacturer with over 30 years of experience, we specialize in creating different types of cable and custom options for industries like medical devices, robotics, automated machinery, audiovisual systems, and more.

From concept to production, our capabilities cover everything: conductor types, insulation materials, shielding designs, and reinforcement options. Whether you need unique shapes, specialized materials, or precise performance, we ensure your cables are built to withstand any environment.

Explore how our production capabilities can bring your ideas to life. With no minimum orders, fast delivery times (as quick as 3 days), and ISO 9001:2015-certified quality, we make the process seamless and efficient.

Contact us today for a quote or technical support and let Winfox provide the perfect custom cable solution for your needs!