PRODUCTS

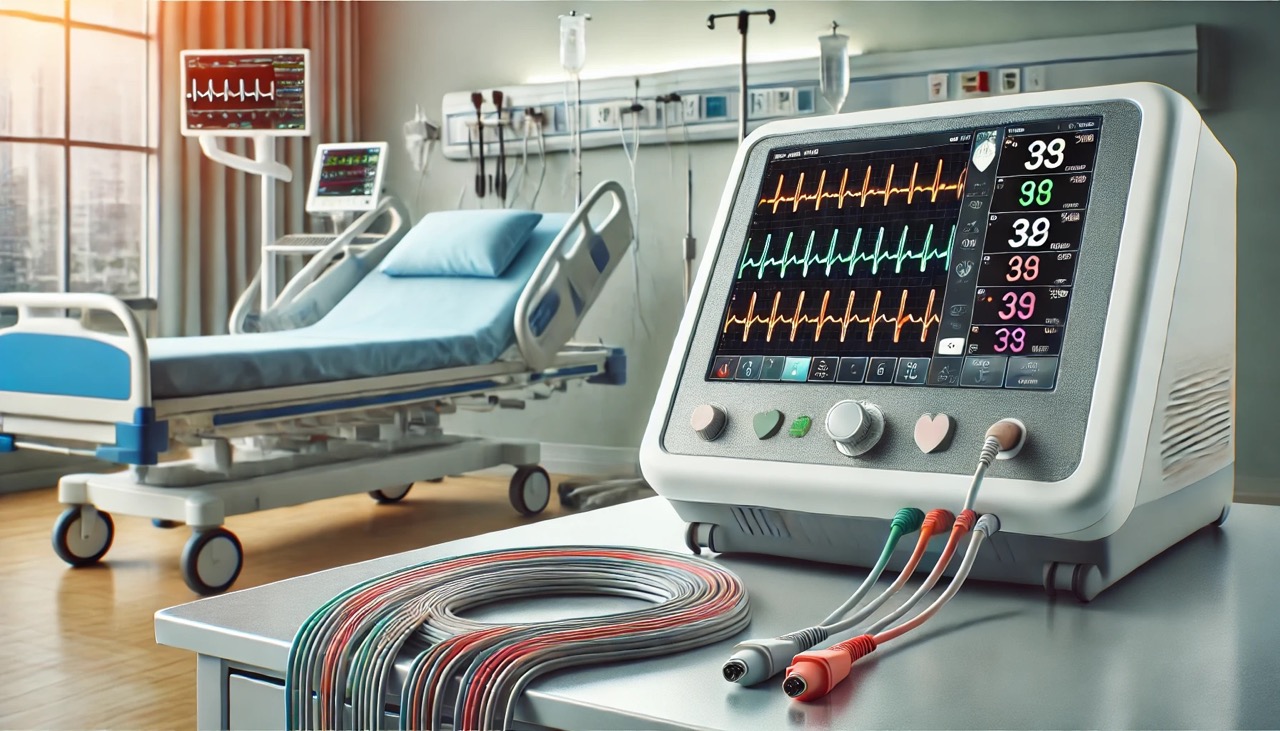

Choose Winfox's premium-quality ECG cables for accurate and reliable signal transmission, durable design, and compatibility with leading devices.

ECG cables and lead wires are the lifeline of cardiac monitoring, connecting electrodes to machines for accurate heart activity analysis. Essential in hospitals, research labs, and portable devices, they demand precision and durability. With 30+ years of expertise, Winfox crafts medical-grade ECG cables tailored to your needs, offering unmatched reliability, certified safety, and superior performance for critical applications.

Contact us to request a quote now and experience precision, durability, and fast delivery with Winfox.

What is ECG Cable?

An ECG (Electrocardiogram) cable is a type of medical cable designed to connect electrodes placed on a patient's body to an ECG machine. These cables record the heart's electrical activity to let healthcare professionals monitor heart rhythms and identify abnormalities. They play a crucial role in cardiac monitoring systems, ensuring accurate signal transmission from the patient to the device.

ECG Cable Attachment: Electrodes

The electrodes capture the electrical signals of the patient’s heart and send them to the monitor. Proper attachment is important for accurate readings and preventing signal interference.

There are two types of electrodes: disposable and reusable. Disposable electrodes are single-use pads with conductive gel that stick directly to the skin. They maintain hygiene and reduce the chances of cross-contamination. Reusable electrodes, made from materials like stainless steel or silver/silver chloride, need to be cleaned and sterilized after each use. They are more cost-effective for long-term use on the same patient.

Types of ECG Cable

There are two primary 2 types of ECG cables: trunk and integrated.

Trunk Cable with Lead Wires

A trunk cable with lead wires consists of a main cable (the trunk) connected to the monitor, with multiple lead wires that attach to the patient’s electrodes. This flexible setup allows adjustments for different patient sizes and electrode placements. The modular design makes it possible to replace damaged lead wires without replacing the entire system. While it is more durable, the lead wires can tangle, and cleaning may require extra effort due to its detachable parts.

Integrated Cables

Integrated cables combine the trunk and lead wires into a single, streamlined unit. This design reduces the risk of tangling and makes setup faster. Since it’s one piece, cleaning and sterilizing is easier, with fewer areas for dirt to hide. However, if a lead wire or connector breaks, the whole cable must be replaced, which can be quite costly. Also, the system lacks flexibility, as you can’t switch between different lead configurations.

Common Applications of ECG Cables

ECG cables are vital in various medical settings. In hospitals, they're used for continuous heart monitoring in intensive care units and during surgeries. For ambulatory monitoring, portable ECG devices utilize these cables to track heart activity as patients go about their daily routines. In research facilities, ECG cables assist in studying heart functions and developing new treatments.

In high-usage settings like ICUs, trunk cables with lead wires are ideal due to their durability and the ability to replace components. For simpler, more portable applications such as ambulatory monitoring or small clinics, integrated cables are a better choice since they offer ease of use and lower maintenance requirements.

ECG Cable vs EKG Cable

There is no difference between ECG and EKG cables. The terms are interchangeable, with ECG being derived from the English "Electrocardiogram" and EKG originating from the German "Elektrokardiogramm." Both refer to the same cardiac monitor cables.

How to Keep ECG Cable Long-Lasting

Proper maintenance of ECG patient cables is crucial for accurate readings and safety. Start by regularly inspecting the cables for signs of wear, such as cracks or fraying, to ensure they’re in good condition.

For cleaning, wipe the cables with a cloth dampened with mild soap and water, avoiding connector immersion. Use approved disinfectant solutions like sodium hypochlorite on the exterior, keeping it away from metal parts.

Store cables neatly to prevent tangling and damage, which helps extend their lifespan. Lastly, routinely test the cables to ensure they transmit signals correctly, helping catch issues early.

Our Manufacturing Capabilities for ECG Cables

|

Medical-Grade Materials for SafetyOur ECG cables are crafted from ISO 10993/USP/FDA-certified biocompatible materials. This ensures patient safety and compliance with international medical standards, making them reliable for critical healthcare environments. |

|

Built for Tough ConditionsEngineered to resist oil, chemicals, heat, and abrasion, our cables thrive in harsh conditions. They withstand sterilization methods like alcohol, ethylene oxide, gamma rays, and autoclave, ensuring long-lasting durability. |

|

Customizable Designs to Meet Your NeedsChoose from various profiles and designs as our ECG cables are fully customizable to fit your unique requirements, whether for prototypes, small batches, or large-scale production. |

|

Low-Noise, Reliable PerformanceThe EC-53-compliant low-noise design ensures accurate and reliable signal transmission. These ECG cables are perfect for patient monitoring and other corresponding medical applications where precision is critical. |

|

Flexible and Easy to HandleDesigned to endure bending, twisting, and constant motion, our ECG cables are both durable and flexible. Their soft construction ensures effortless installation and handling, saving time during setup. |

|

Fast Delivery, No Minimum OrderWe prioritize speed without sacrificing quality, offering delivery within 3 days to 2 weeks. With no minimum order quantity, we cater to all project sizes, from prototypes to full-scale production. |

Contact us today via the button below to design medical-grade ECG cables tailored to your exact specifications.

How to Order Custom ECG Cables from Winfox

Step 1: Share Your ECG Cable Requirements

Let us know your exact needs—connector types, lead configurations, lengths, and intended use. We’ll work closely with you to get the details right.

Step 2: Design Review & Optimization

Our engineers review your specifications, optimizing the design for medical accuracy, durability, and cost-effectiveness, ensuring it meets all necessary standards.

Step 3: Get a Fast Quotation

Receive a clear and detailed quote outlining pricing, lead times, and key production details, giving you confidence to proceed.

Step 4: Sample Creation

We create a prototype ECG cable tailored to your requirements, ready for thorough testing and feedback.

Step 5: Confirm & Finalize

Approve the sample or request adjustments to ensure the final design aligns perfectly with your needs.

Step 6: Precision Manufacturing

Production begins with medical-grade materials, stringent quality checks, and compliance with ISO 13485 standards for healthcare devices.

Step 7: Reliable Shipping

Your custom ECG cables are securely packed and delivered within 3 days to 2 weeks, depending on order size and location.

Ready to Build the Perfect ECG Cable? Contact Winfox today for precise, reliable, and fully customized ECG cables that meet the highest medical standards!

How to Design ECG Cables

When designing a cable for heart monitoring, it’s essential to prioritize accurate signal transmission and patient safety. Careful consideration of materials, insulation, and compliance with medical standards ensures optimal performance and reliability.

Lead Configuration

Think of the leads as the “arms” of your ECG system as they reach out to capture electrical signals from the heart. The number of leads you need depends on different needs:

- For Basic Monitoring: When monitoring heart rhythm in settings like hospitals or during surgery, 3 or 5 leads are often used. These setups provide essential information and help detect irregularities in the heartbeat.

- For a Full Diagnostic Picture: To gain a more detailed view—such as assessing for heart attacks or other conditions—a 10-lead setup is typically utilized. This offers a comprehensive perspective on the heart’s electrical activity, supporting accurate diagnoses.

Choosing the right configuration for the ECG lead wire ensures you collect the necessary data without unnecessary complexity. Too many leads for basic monitoring might be excessive, while too few during diagnostic testing risk missing important information.

Cable Length

It is important to consider the cable length to balance patient comfort and signal quality. Cables that are too short can restrict patient movement, while excessively long cables may introduce signal noise and become cumbersome.

Connector Type and Compatibility

Using the wrong connectors can cause weak connections, inaccurate readings, or equipment damage. Always double-check that the connectors match your machine’s specifications before choosing ECG cables.

Some ECG machines require proprietary connectors that are specific to a particular brand or model. These ensure a snug, secure fit but can be limiting if you’re using different devices. On the other hand, universal connectors are more flexible and work across multiple systems.

Also, depending on the electrodes you're using, you might need pin-style, clip-style, or snap-style connectors. Pin (Banana) connectors plug into the electrode or an adapter. They are reliable and commonly used in different clinical settings, but come with a higher price.

For clip connectors, these essentially "clip" onto tab electrodes or directly onto the patient's limbs. They are useful in situations where rapid attachment and detachment are necessary. Snap connectors literally “snap” onto the electrode. Snap connectors are often preferred in busy environments, like emergency rooms, since they’re quicker and easier to use.

Materials

The outer coating of the cable protects the inner wires. Most ECG cables use medical-grade PVC (polyvinyl chloride), TPE(thermoplastic elastomer

) or TPU (thermoplastic polyurethane). PVC is durable and affordable, but TPE is more flexible and often preferred for patient comfort. TPU shows excellent resistance to various cleaning agents, including alcohol-based solutions, making it a great choice for long-term use.

Also, materials like silicone are particularly suited for steam autoclaving for ECG cables due to their ability to withstand high temperatures and moisture without degrading. This compatibility is essential for maintaining sterility in medical environments.

The wires inside the cable need to transmit the heart's electrical signals without distortion. Copper is a standard choice for its excellent conductivity and durability. Some high-end cables use silver-coated copper for even better signal quality.

Noise Reduction

Reducing noise in ECG cables is crucial for obtaining accurate heart readings. By adding a noise reduction layer, is an effective way to block outside interference. By wrapping cables with foil or braided wire, you can prevent electromagnetic noise from disrupting signals.

Biocompatibility

Biocompatibility isn’t just about comfort—it’s about ensuring the cables won’t cause harm to patients. Non-compliant materials can lead to redness, rashes, infections, or even worse outcomes, especially in sensitive populations, such as infants.

ECG cables should use gentle materials on the skin and are unlikely to cause irritation or allergic reactions. Hypoallergenic cables, free from common allergens like latex or phthalates, are ideal for minimizing discomfort. For continuous monitoring, biocompatible materials like medical-grade silicone or TPU/TPR are preferred due to their softness, flexibility, and non-reactive nature. In general, using materials that are compliant with ISO10993, USP class VI

Or the FDA is essential.

Compliance with Standards

Ensuring that ECG cables comply with established standards is crucial for patient safety and the accurate functioning of medical devices.

The ANSI/AAMI EC53 standard outlines key requirements for ECG cables and lead wires, addressing factors such as lead resistance, flex life, tensile strength, and noise levels. For biocompatibility, cables that meet international standards, such as ISO 10993, are rigorously tested for safety. They avoid releasing harmful substances or causing adverse effects during use.

Winfox - the Top-tier ECG Cable Supplier for You

When standard ECG cables don’t meet your requirements, Winfox offers fully customizable solutions designed specifically for your medical devices, ensuring the ideal fit and performance. With over 30 years of expertise, we specialize in designing high-performance ECG cables that combine durability, accuracy, and patient safety. Our customization capabilities ensure your cables meet precise medical standards. Whether you need disposable or reusable cables, we deliver solutions fit for any environment and application.

With ISO 13485 and 9001:2015-certified quality, no minimum orders, a diverse range of cable types, and delivery as fast as 3 days, Winfox makes the process seamless. Contact us today for a quote or technical support and discover how our production capabilities can bring your perfect ECG cable to life!