PRODUCTS

Medical cables are the lifeline of modern healthcare equipment, ensuring the seamless transmission of signals, data, and power across various medical applications. At Winfox Cable Solution, we specialize in manufacturing high-performance medical-grade cables designed for reliability and precision in critical environments. With over 30 years of experience, our custom medical device cables are built to meet your specific requirements, whether you need small production runs or advanced hybrid constructions.

Our cables for medical devices are built for strength and flexibility, ensuring they stand up to the toughest conditions. Crafted from ISO 10993/USP/FDA-certified biocompatible materials, our cables meet the highest safety standards. With ISO 9001:2015 and ISO 13485 certifications, all of our cables are designed to endure multiple sterilization methods, including alcohol, ethylene oxide, gamma rays, and autoclave. Whether you need precision for patient monitoring or durability for surgical tools, our EC-53 low-noise cables deliver reliable performance. Furthermore, with a variety of profiles and configurations available, we can tailor solutions to fit your exact needs.

Elevate your equipment's performance with Winfox's tailored cable solutions. Contact us today to explore how our expertise and industry-leading certifications can meet your exact needs, and trust us to be your go-to partner for all your medical cable needs!

Applications of Medical Cables

Cables for medical devices are essential components across various healthcare settings, ensuring seamless transmission of signals, data, and power. These cables are engineered to meet the high-performance demands of operating rooms, diagnostic labs, and critical care units. Designed to withstand rigorous conditions—such as frequent handling, sterilization, and exposure to contaminants—they play a vital role in ensuring patient safety and precise medical outcomes. Below is an overview of key applications across medical fields:

- ECG (Electrocardiogram)

ECG cables are used to monitor heart activity, transmitting electrical signals from the patient to the monitoring system with high signal integrity. These cables are built for flexibility, multiple use, and reliable sterilization to support accurate, real-time diagnostics. - Dental Applications

Dental cables connect handpieces, ultrasonic scalers, and other devices to power sources or data systems. They are designed to endure moisture, sterilization, and frequent use, ensuring flexibility, durability, and biocompatibility for patient safety. - Oximetry

Cables for pulse oximeters transmit real-time data measuring oxygen levels in the blood, a critical parameter in surgeries and intensive care units. These cables are lightweight, easy to sterilize, and comfortable for patients, ensuring uninterrupted monitoring. - Aesthetic Medicine

Medical cables are integral to devices used in laser treatments and cosmetic procedures. They require high flexibility, durability, and patient safety while withstanding frequent sterilization during treatments. - Imaging Diagnostics

Imaging equipment such as X-ray, MRI, and CT machines rely on cables to transmit data and signals needed to produce clear medical images. These cables are shielded to minimize electromagnetic interference, ensuring signal precision and diagnostic accuracy. - Rehabilitation Devices

Cables used in rehabilitation connect devices such as muscle stimulators and mobility aids, designed to be flexible and durable. They ensure comfort for patients during prolonged use and provide reliable performance throughout recovery sessions. - Life-Saving Interventions

Cables for defibrillators and monitoring devices play a crucial role in emergencies, transmitting electrical charges and real-time data to support immediate medical decisions. These cables are built for reliability in high-pressure situations. - Surgical Procedures

In surgeries, cables connect electrosurgical scalpels and robotic systems to power sources. They are designed to withstand sterilization, resist contamination, and offer precise control, ensuring safety and optimal performance throughout procedures.

Types of Medical Cables

-

Endoscope Cables – Flexible, durable, and capable of transmitting video signals during minimally invasive procedures.

-

Dental Equipment Cables – Provide power and data to tools such as handpieces and scalers, built for frequent use and sterilization.

-

SpO₂ Sensor Cables – Measure oxygen levels in real-time, essential in surgeries, anesthesia, and critical care.

-

Defibrillator Cables – Deliver high-voltage electrical charges for life-saving interventions, designed for reliability under pressure.

-

ECG, EKG, and EEG Cables – Accurately transmit heart and brain signals, ensuring dependable diagnostics.

-

Surgical Scalpel Cables – Power electrosurgical tools, designed to withstand heat and repeated sterilization.

-

IBP Cables – Connect pressure transducers to monitors for real-time invasive blood pressure tracking in critical care.

-

NIBP Cables – Transmit non-invasive blood pressure data via cuffs, offering consistent performance across healthcare settings.

-

MRI Cables – Designed to function within the strong magnetic fields of MRI machines, these cables transmit vital imaging data without interference.

Factors to Consider When Designing/Choosing Medical Cable

When selecting medical cable, quality, and reliability are non-negotiable. Faulty cables can jeopardize patient safety, endanger healthcare staff, and damage a facility's reputation. Consistent performance ensures uninterrupted care, avoids costly repairs, and maintains trust in medical services. Every detail matters in delivering high-quality healthcare. Here are the key factors to consider:

Durability

Medical cables play a vital role in healthcare applications and must be designed to withstand frequent bending, movement, and mechanical stress. To achieve this, manufacturers often use high-flex-life materials like thermoplastic elastomers (TPE), polyurethane (TPU), and silicone, which offer outstanding flexibility and durability. These materials are engineered to prevent cracking or breakage, which is crucial for cables in dynamic environments such as patient monitoring systems and endoscopic devices. By ensuring reliable performance over time, these durable cables reduce the need for premature replacements, ultimately enhancing operational efficiency in medical settings.

Electrical Performance and Noise Reduction

In medical devices, minimizing electromagnetic interference (EMI) and signal noise is essential for ensuring accurate data transmission. Even brief disruptions in the transmission can compromise patient care and lead to misinterpretations of a patient’s condition or even life-threatening situations. This is particularly important in sensitive devices like EEG and ECG machines.

High-quality medical cables incorporate shielding materials, such as copper braiding and aluminum foil, to block external interference and maintain signal integrity and continuity. Moreover, low-noise cables that comply with the AAMI EC53 standard are designed to reduce electrical noise, providing clear and reliable readings.

Bioburden Control

In sterile medical environments, controlling bioburden is essential to minimize bacterial contamination and ensure patient safety. Medical cables often undergo bioburden control processes to achieve this, particularly for reusable options that need to withstand repeated sterilization. In addition, incorporating anti-bacterial materials into cable designs can inhibit the growth of harmful microorganisms. These materials provide an extra layer of protection, making them especially valuable in high-risk settings like operating rooms and intensive care units, where the risk of infection must be meticulously managed.

Biocompatibility Materials

For medical cables that come into contact with human skin or internal tissues, biocompatibility is paramount. Materials such as polyvinyl chloride (PVC), silicone, and TPU are commonly chosen because they meet stringent regulatory standards like ISO 10993, USP Class VI, and FDA approvals. These materials undergo rigorous testing to ensure they are safe for direct or indirect contact with the body, making them ideal for applications such as ECG electrodes, defibrillators, and surgical instruments. Silicone is particularly valued in invasive devices due to its excellent flexibility and ability to maintain sterility, ensuring patient safety.

Sterilization Compatibility

In sterile medical environments, cables frequently undergo multiple sterilization processes to maintain a germ-free condition. This compatibility is essential for reusable cables, which must endure various sterilization methods such as autoclaving, alcohol, ethylene oxide (EtO), gamma radiation, and chemical disinfectants. Materials like silicone, TPR, and fluoropolymer (FEP/PFA/ETFE) excel in this regard, as they resist degradation from high temperatures and aggressive chemicals. At the same time, TPE and PVC may handle gamma sterilization but have limited sterilization cycles.

Chemical Resistance

Medical cables are often exposed to disinfectants, bodily fluids, and various chemicals, necessitating materials that resist degradation. Fluoropolymers like PTFE (Teflon) and

FEP/ETFE/PFA are excellent choices due to their outstanding chemical resistance, allowing them to withstand regular exposure to harsh cleaning agents without compromising performance. This characteristic is especially crucial in critical care settings and laboratory instruments, where maintaining the integrity of cables is vital for ensuring patient safety and reliable operation of medical equipment.

Disposable or Reusable Applications

Choosing between disposable and reusable cables in medical applications depends on the intended use and infection control protocols. Disposable cables, often made from cost-effective materials like PVC, are ideal for single-use scenarios, minimizing the risk of cross-contamination. In contrast, reusable cables are designed for durability and constructed from robust materials that can withstand repeated sterilization without losing functionality. This balance ensures that medical equipment remains reliable and safe for patient use while considering cost-effectiveness in healthcare settings.

Regulatory Compliance

Compliance with international standards is crucial when selecting medical cables and manufacturers, as it ensures the safety, performance, and reliability required in medical environments. Standards such as ISO 13485 focus on quality management systems for medical devices, while IEC 60601 addresses electrical safety in medical equipment. Also, UL (Underwriters Laboratories) certification verifies that cables meet stringent fire resistance and safety requirements, which is particularly important in hospital settings. Adhering to these standards protects both patients and healthcare providers, fostering trust in the medical devices used for treatment.

Customization and Hybrid Construction

In the diverse landscape of medical devices, customization is often necessary to meet specific application needs. Tailored cable assemblies allow for custom solutions that can integrate power, data, and signal transmission within a single assembly, known as hybrid cables. This design reduces clutter and simplifies setups in environments with limited space. Such custom configurations are essential for sensor cables in diagnostic devices, where precise specifications directly impact the effectiveness and reliability of medical treatments.

Winfox Provides You with the Best Solutions for Medical Cables Need

Winfox provides custom solutions to meet all your medical cable needs. Whether you're looking for durable, sterilization-friendly cables for ECG, dental, or other devices, our expertise ensures reliability and safety. With over 30 years of experience and a wealth of patents, and multiple types of cables, we specialize in custom medical cables that precisely meet your application’s requirements, offering advanced insulation, superior shielding, and biocompatibility. Our expertise ensures that every cable is designed to deliver optimal performance, reliability, and safety in the most demanding medical environments.

Our comprehensive range of solutions covers every aspect of medical cable design, from complex multi-conductor assemblies to hybrid cables, all tailored to meet the unique demands of modern medical equipment. As an ISO 9001:2015 and ISO 13485 certified manufacturer, we ensure that all our products meet the highest standards of quality, safety, and performance, delivering reliable solutions that comply with stringent medical regulations. For tailored cable designs that meet the stringent demands of medical applications, Winfox is your trusted partner. Discover how our custom cable service can enhance your devices' performance and longevity. Contact us today for innovative, high-quality solutions built to your specifications.

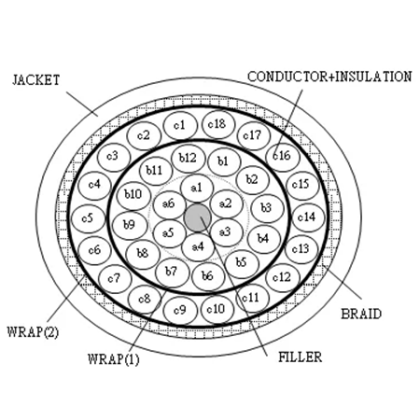

medical cable-4

Due to product images are only for the brief concepts and ideas, if you can't find any information or product you need in this page, please feel free to Contact us directly.

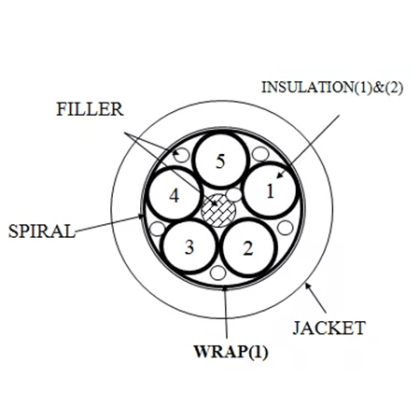

medical cable-3

Due to product images are only for the brief concepts and ideas, if you can't find any information or product you need in this page, please feel free to Contact us directly.

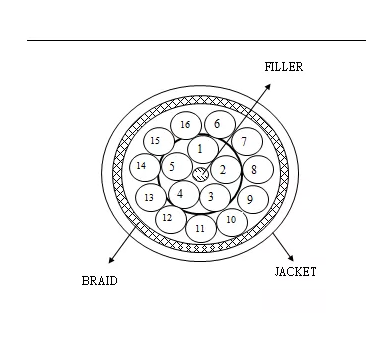

medical cable-1

Due to product images are only for the brief concepts and ideas, if you can't find any information or product you need in this page, please feel free to Contact us directly.

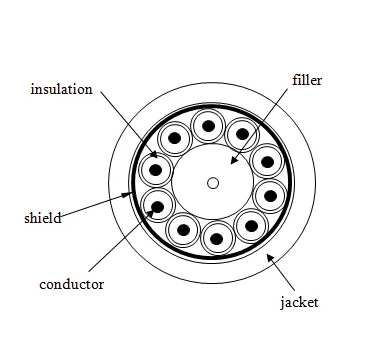

medical cable-2

Due to product images are only for the brief concepts and ideas, if you can't find any information or product you need in this page, please feel free to Contact us directly.